From Scanning to 3D Bioprinting - BAB Does It All

- Advanced Solutions

- Feb 17, 2021

- 2 min read

Updated: Jun 14, 2022

The enhanced scanning capabilities and associated TSIM® workflows enable the precise printing of structures onto contoured surfaces

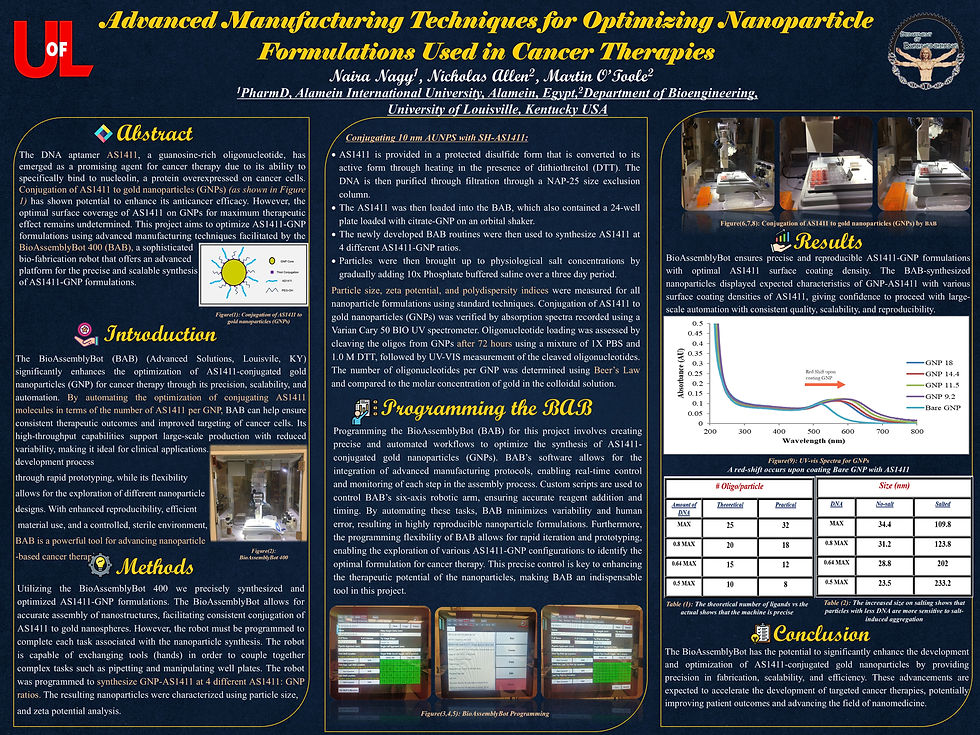

3D bioprinting technology platforms typically use gantry axes (X, Y, and Z) as their method of motion control. This enables additive manufacturing, a layer by layer approach to 3D printing, where new constructs are fabricated from the bottom-up in the Z direction. However, to fabricate complex biological constructs and eventually larger organ systems, more freedom of movement is required to meet all fabrication tasks. The BioAssemblyBot® platform, with its 6-axis robotic arm at the center of the platform, has the needed flexibility in print-path motion and directional access; with the added ability to execute a print task from a variety of angles. Further enabling such a workflow, the system visualizes surface features of complex objects within the fabrication envelope, incorporating such features in the 3D digital model. Through unique tool sets that are included with the BioAssemblyBot®, as well as a built-in workflow within the TSIM® software program, this workflow is now achieved.

The Process

The TSIM® design software when coupled with a BioAssemblyBot® facilitates the capture of high-resolution surface data from objects placed on the BioAssemblyBot® printing surface. Utilizing a laser measurement sensor with submillimeter repeatable accuracy, the surface height is measured across a chosen area and then saved on a local storage device in a simple point cloud format. Any network connected PC running the TSIM® design software can request the point cloud data from the BioAssemblyBot®. After receiving the point cloud, TSIM® automatically filters the data and reconstructs the surface as a triangulated mesh within the TSIM® solid modeling environment. In this form, the surface can be used as a projection target for custom non-planar printing tool paths enabled by the BioAssemblyBot® six-axis robotic manipulator. They’re also highly useful as a visual reference for a variety of bioprinting design and assembly tasks.

Workflow example using a patient-derived heart model

In this example, a patch is being printed onto the complex surface of a printed three-dimension model of a heart, generated from patient data.

Step 1: Scanned surface

The first step of this workflow includes the utilization of 3D Laser Scan BioAssemblyTool to scan the surface of the object and import that data into the TSIM® Software Program. In this example, a section of the surface of the heart is the focus of the scan area.

Step 2: Cardiac patch sketch

Using the sketching tools within the TSIM® software program, two example patterns are created de novo.

Step 3: Patch generated into 3D model

After the sketch is completed, the 3D model is generated and ready to be placed on the appropriate location on the model.

Step 4: Patch is projected onto surface of model

The appropriate material is assigned to the design which then instructs the system on how to complete the print the task. Now you are ready to print!

Step 5: Print

The image below represents the completed print after being printed on the BioAssemblyBot 400 using the 3D Syringe BioAssemblyTool.

Watch the process:

Comments